| NUMBER #1 DERMA SOLUTION PROVIDER |

CUSTOMIZED & INNOVATIVE FORMULATIONS |

Manufacturing

OUR PLANT.... We create the future of cosmetics

AQMED manufacturing plant is a state-of-the-art production facility situated in Anand(Kheda), Gujarat. We have well-equipped machineries, trained manpower and a robust R&D Facility which help deliver products that cater to international standards.

The plant also consists of effective infrastructure and an eco-friendly work environment which help in making us leaders in the ‘Private Labelling’ sector.

Our advanced manufacturing facilities enable efficient and consistent development of high-quality products.

Our dedication to quality and trust means we work with our customers to deliver the best products, transparently, through all stages of production.

Pharmaceutical Block

Ointment manufacturing lines of 150kg.

High speed tube filling lines and Lotion filling line.

Cosmetic Block

One automatic ointment manufacturing line of 1500 Kg, 500kg and one planetary mixer of 150kg.

One high speed Automated tube filling line and Automated Liquid filling line, Lotion filling line.

Capacities

| Dosage Form | Capacity per annum |

|---|---|

| Cosmetic Creams, Gels | 5 million |

| Cosmetic Lotions, Solutions, Serum | 5 million |

| Pharma Ointments, Creams, Gels | 5 million |

| Pharma Lotions | 5 million |

WHAT MAKES OUR MANUFACTURING PLANT STAND OUT!

- Spread across 48,500 sq. ft.

- FDA approved 19,000 sq. ft. R.C.C. production plan

- Capable of cGMP/ ISO/ USFDA standards of manufacturing and quality standards.

- All manufacturing and filling areas maintained under class D (HEPA Filters) with Epoxy flooring and all walls of production area are covered with clean room partition, which ensures cleanliness and hygiene

- Separate man and material entry air locks for each manufacturing area as well as filling rooms.

- Biometric access control in core areas to restrict unauthorized personnel entry.

- Utilities include compressed air system, diesel generators, and effluent treatment plant.

- Each zone has separate AHUs (Air Handling Units), dehumidification unit and dust extraction systems

- Segregation of every critical processing activity in each zone, to avoid cross-contamination

- Hi-tech laboratory setup for product innovation and testing

- CCTV camera setup throughout the factory for complete safety and security

- Adherence to each processing stage viz. 100, 1,000, 10,000, 100,000 with respect to room air changes, pressure, particle count, flow direction etc.

- HVAC system with separate AHU’s for each processing area to maintain Classification.

- Respective zones, areas and even uniforms marked with specific colours to ensure total segregation

- Duo Pass Reverse Osmosis (RO) water system/ de-mineralization plant

- Zero-discharge Effluent Treatment Plant

- Fully computerized individual/ separate office administrative building with latest communication facilities along with server room

- Sufficient warehouse for raw materials and packaging materials with segregation.

- We have provided material management software for unified production planning.

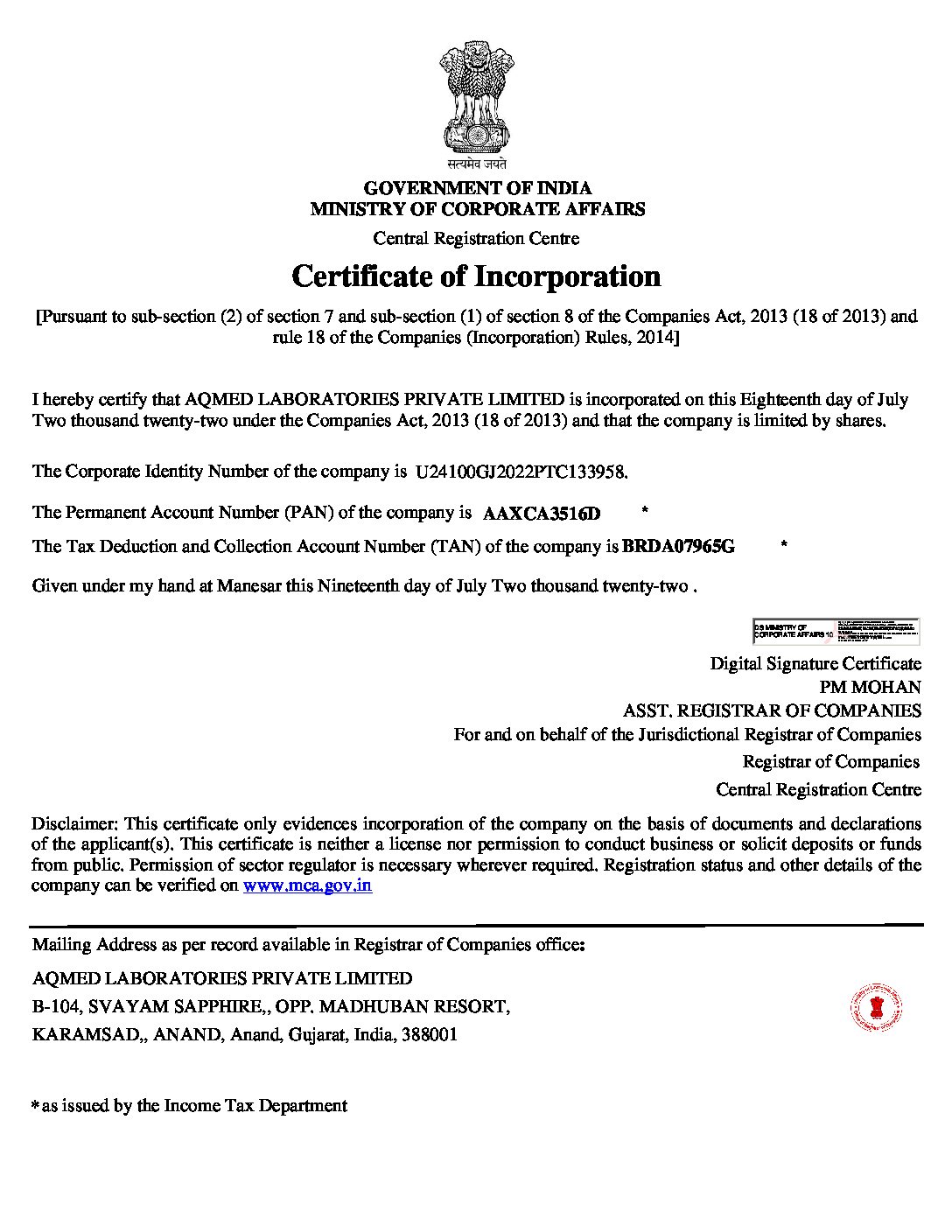

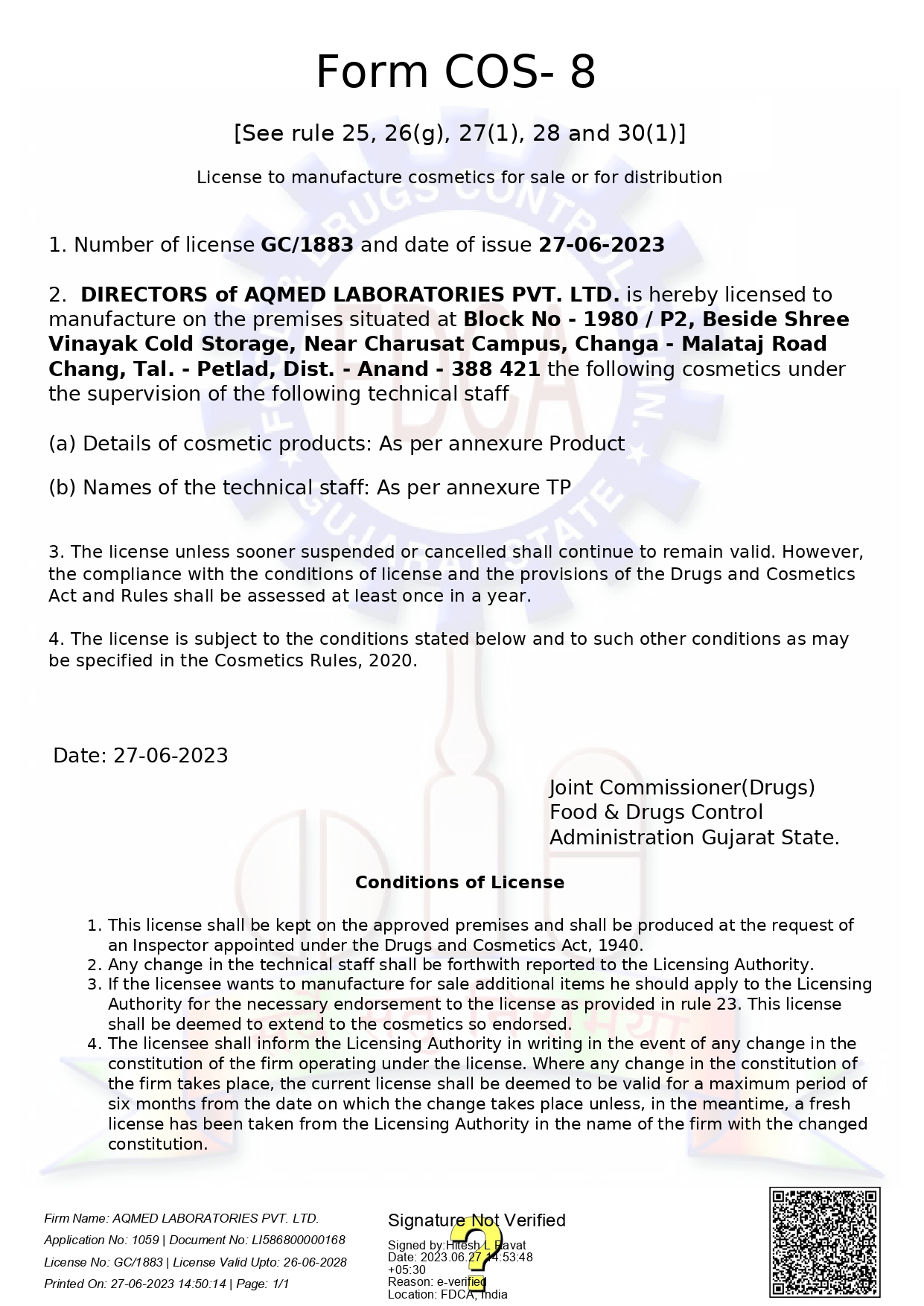

ACCREDITATION

Our manufacturing facilities are accredited to government norms and regulations round-the-clock. Our manufacturing facility and lab are in compliance with GMP, WHO GMP certified and D&B D-U-N-S Registered/US FEI Number Received as per MoCRA Guidance.

All products manufactured at AQMED Laboratories are approved by the FDA of Gujarat.

Our Team

Production

5

Quality Assurance

2

Quality Control

3

Shop floor workforce

40+

Engineering & Maintenance

2

Administration

2

Stores

2

Quality Control and Quality Assurance

We have a well-equipped Quality Control and Quality Assurance department with sophisticated analytical instruments. Documentation such as SOPs, calibration, and validation records are maintained assiduously and all documented procedures are strictly followed at all levels. An excellent Formulation and Development laboratory is utilized to optimize our existing formulations, improve processes, and develop new products.

- A well-equipped lab with instruments such as UV-Vis spectrophotometer, Karl Fisher titrator, viscometer, and Stability chambers (3) are provided for in house testing of all products.

- We have identified dedicated area for microbiology lab.

Major Manufacturing, Quality Control, Utility Equipment

| Equipment | Make |

|---|---|

| Ointment Mfg. Plant (150 kg) | CHAMUNDA PHARMA |

| Ointment Mfg. Plant (500 kg) | CHAMUNDA PHARMA |

| Tube Filling Machine 40 tubes/min | BHAVANI ENG. |

| Liquid filling machine | BHAVANI ENG. |

| Semi-solid (Lotion) filling machine | BHAVANI ENG. |

| Labelling machine (Round and flat bottle) | RADHE PHARMA |

| Analytical balance | AXPERT |

| RM sample weighing Balance | AXPERT |

| RLAF for Dispensing and Sampling (4 nos.) | CLEANZOFEB |

| Air Compressor 20 hp | EMPIRE |

| HVAC system | CLEANAIR |

| Purified RO Water System with MB 500 lit/hr | PRAYOSHA |

| Stability Chamber (1000 ltr) (3 nos.) | AUDITA |

| Viscometer | Lab-India |

| UV-Vis Spectrophotometer | Lab-India |

| ‘pH meter | THERMO |

| Conductivity meter | THERMO |

| Analytical balance | AXPERT |

PLAN YOUR VISIT

Follow Us

Have A Business Idea In Your Mind?

AQMED Laboratories is the most trusted best cosmetic manufacturer in Ahmedabad, India.